RAPTOR® Polymer Composite Staples

Technical Information and Properties

RAPTOR® PLASTIC COMPOSITE STAPLES hold better than metal staples in tensile, but are weaker in shear strength. RAPTOR® staples are UV resistant and chemical resistant. They do not become more brittle at low temperatures, and they retain their strength at high temperatures.

BUY NOWat RAPTOR® Webstore

Request Information

FORM

HOLDING STRENGTH

RAPTOR® composite staples have stronger tensile holding power compared to similar sized metal staples.

MECHANICAL PROPERTIES

| TENSILE PEAK FORCE DATA | |

| RAPTOR® | 24 lbs. |

| METAL | 16 lbs. |

| SHEAR PEAK FORCE DATA | |

| RAPTOR® | 25 lbs. |

| METAL | 47 lbs. |

TENSILE DIRECTION

SHEAR DIRECTION

CHEMICAL RESISTANCE

RAPTOR® polymer composite staples have strong resistance to chemicals and maintain their strength even after long-term immersion in most liquids including organic solvents, aqueous solutions and automotive fluids such as these listed to the right:

CHEMICAL RESISTANCE

| ORGANIC SOLVENTS | AQUEOUS SOLUTIONS | AUTOMOTIVE FLUIDS |

| Alcohol | Acid | Gasoline |

| Acetone | Base | Oil |

| Trichoroethylene | Saline | Grease |

THERMAL PROPERTIES

- Drivability performance unaffected by low temperatures (Tested down to -30°F).

- Continuous Use Temperature: 350°F

- Short Duration Temperature Limit: 500°F

- Ash Temperature: 900°F

DIFFERENT GRADES

-

STANDARD MATERIAL:

Provides best drivability; will damage high speed steel moulder knives.

-

LF MATERIAL:

Safe for most moulder blades; drivability is somewhat compromised.

-

NF MATERIAL:

Safe for all delicate blades; drivability is somewhat compromised.

PULPABILITY

RAPTOR® composite staples have been tested in the Kraft® process and do not dissolve or melt. The composite material is 100% recoverable and the density is 1.6 g/cm3 .

RAPTOR® AT COLD TEMPS, HIGH TEMPS AND UV EXPOSURE

RAPTOR® LOW/HIGH TEMP PERFORMANCE

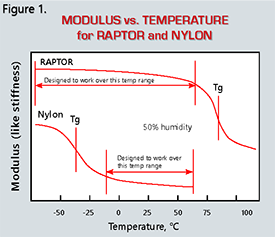

RAPTOR® polymers have an optimum operating temperature range (at which they can be driven) from at least -50C (-58F) to at least 65C (150F), while polymers used for staples such as the Kowa brand have an optimum operating temperature range from about -10C (15F) to about 65C(150F). RAPTOR® can be successfully driven at very low or quite high temperatures. The technical reasons for these differences are described below.

Polymers undergo a dramatic change in properties at a temperature that is unique to each polymer. This temperature is called the glass transition temperature (Tg). The glass transition takes place over a temperature range. When the polymer is cooled below this temperature, it becomes hard and brittle. Above the Tg, it can be tough or rubbery. Depending on the application, polymers may be used above their glass transition temperature, or below their glass transition temperature. If a polymer is below its Tg, it is brittle. This does not mean poor performance for an application unless it actually fails. The Tg does not put a lower limit on the service temperature for end-use polymers, it simply indicates the temperature at which brittle fracture becomes the dominant failure mechanism.

Polymers that have a Tg greater than ambient temperature are in the glassy/brittle state at ambient temperature. Examples of these are plastics such as PS, PMMA and PET. These plastics tend to be brittle and, if they are stressed beyond their design, they will fail in a brittle manner. They are successfully used for thousands of applications even though they are brittle. The RAPTOR® composite has a Tg about 120°C and its Tg does not change much with humidity. RAPTOR® composite is designed to be driven into a substrate when it is BELOW its Tg, whether it is driven at 105°C or at -40°C. Driving into a substrate is the most demanding requirement for impact driven fasteners. Since RAPTOR® is already below its Tg, temperatures colder than -40°C will not change the drivability of the RAPTOR® fastener measurably.

Nylon is a polymer that is used for non-RAPTOR® plastic staples and it has a Tg about -20°C for typical humidity in the U.S. For applications using nylon, the material is ABOVE its Tg. When using nylon at lower temperatures, the material becomes brittle and no longer functions as intended. It will fail when trying to drive it as an impact driven fastener at low temperatures. This type of material exhibits a dramatic change in performance as the temperature gets colder.

MODULUS vs. TEMPERATURE

for RAPTOR® and NYLON

Figure 1 demonstrates this behavior. The graph of modulus vs temperature for polymers shows a dramatic drop in modulus indicating the Tg. Modulus is somewhat like stiffness. This figure is not intended to show that higher modulus is a better product, but to show where ambient temperature is relative to RAPTOR® Tg and to nylon Tg. It shows that decreasing the temperature can change the properties of nylon dramatically, but will affect the properties for RAPTOR® very little.

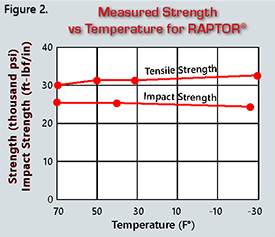

STRENGTH vs. TEMPERATURE for RAPTOR®

This is reinforced in Figure 2 which shows actual tensile strength and actual impact strength for the RAPTOR® composite nails as a function of temperature, demonstrating that these properties do not change much with temperature for the RAPTOR® composite nails.

Finally, the properties of the RAPTOR® composite may not be the only considerations for successful driving RAPTOR® at low temperatures. Tool performance and frozen wood could affect drivability of RAPTOR® at low temperatures, so tests were done in a cold room at -40°C (-40F) with frozen pine, poplar, MDF and oak with tools and fasteners and wood conditioned to this temperature. Analysis of the results showed there was NO difference in drivability performance at -40°C (-40F) compared to drivability performance at 23°C (74F).

RAPTOR® HOLDING STRENGTH WITH CHANGES IN TEMPERATURE

Once RAPTOR® is driven, the forces on the staple due to temperature changes should be small. The coefficient of thermal expansion for the RAPTOR® composite material and for wood is not dramatically different (see table below, medium density wood is listed), so any forces from dissimilar expansion will be small. We have had no issues with the installed RAPTOR® fastener failing due to changes in temperature.

| MATERIAL | COEFFICIENT OF THERMAL EXPANSION |

| RAPTOR® composite (flow direction) | 8 x 106 per ℉ |

| Wood, parallel to grain | 2 x 106 per ℉ |

| Wood, perpendicular to grain | 14 x 106 per ℉ |

| Wood, end grain | 17 x 106 per ℉ |

If RAPTOR® is driven into wood and then the temperature is raised above the Tg, RAPTOR® will continue to hold because the reinforcing fibers and the crystalline structure remain intact. RAPTOR® can be continuously used at 150°C and can be used for short duration at 260°C (after being driven at lower temperatures).

ULTRAVIOLET LIGHT STABILITY

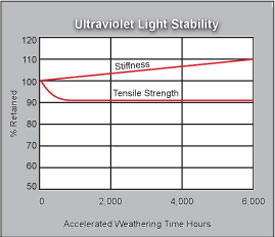

The UV resistance of the RAPTOR® composite has been tested and found to change less than 10% over 6000 exposure hours (see Figure 3).

This slight degradation could have some slight effect on the drivability and on the holding power, but RAPTOR® will not degrade and lose significant properties from sun exposure. RAPTOR® composite nails maintain their strength even after 6,000 hours of accelerated aging by exposure to UV

and moisture.

Since 1993

Since 1993